Sigma Polishers

Sigma Polishers

Quantity Discount

Buy 3 - Save 10%Buy 6 - Save 20%(Mix/Match All Rotary)

- SKU:

- Choose Options

- Availability:

- In Stock

Designed for the unique demands of dental porcelains

Sigma Polishers are engineered specifically for finishing and polishing feldspathic porcelain, giving technicians the right balance of control and efficiency. Their specialized design makes it possible to achieve smooth adjustments and a natural, high-gloss finish with only a light touch. Consistent performance across shapes ensures dependable results on every porcelain restoration.

What makes Sigma Polishers different?

Unlike general-purpose polishers, Sigma is tailored specifically for porcelain’s unique properties. Their carefully balanced construction delivers controlled material removal with minimal pressure, reducing the risk of chipping or altering fine anatomy. The result is a smoother workflow where technicians can contour, blend, and finish porcelain restorations with confidence.

Key Benefits of Sigma Polishers

- Purpose-built for conventional dental porcelain

- Delivers smooth adjustments with only a light touch

- Reduces risk of chipping or altering fine anatomy

- Wear-resistant construction with a high diamond concentration

- Available in coarse, medium, and fine grits for different stages of finishing

Shapes and grits for every stage of finishing

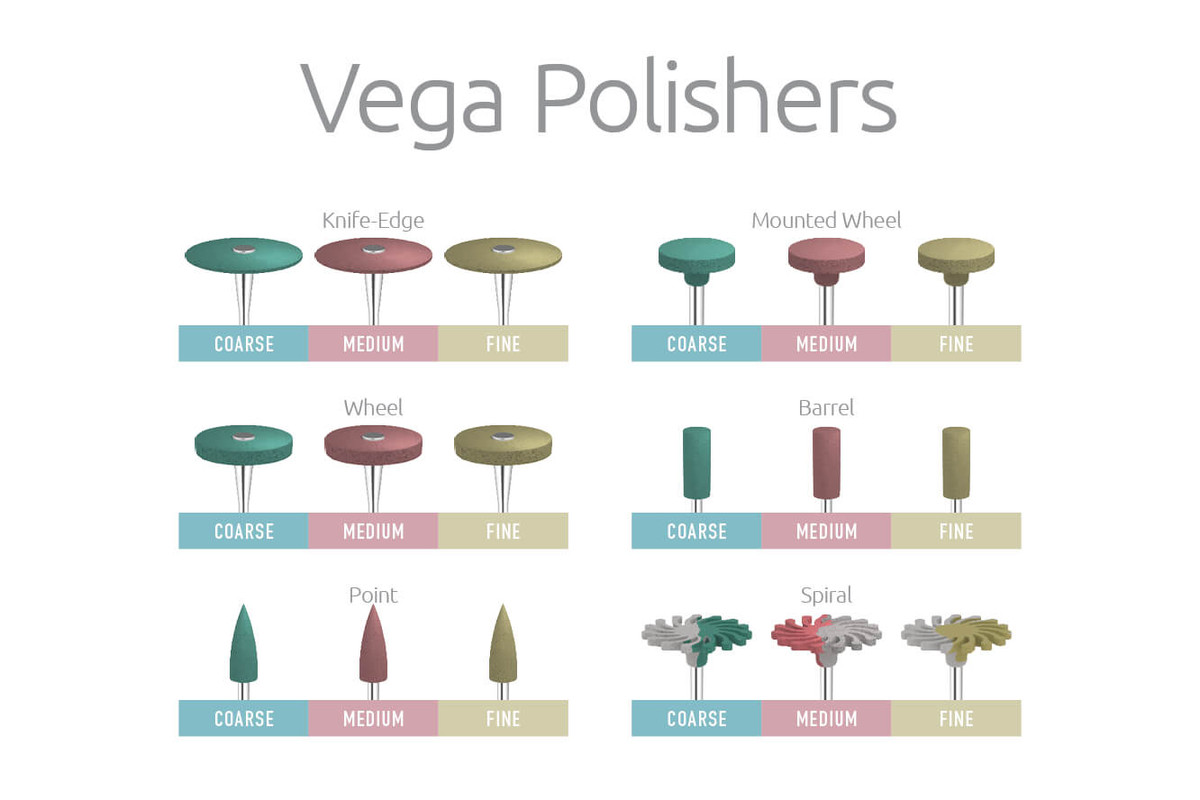

Sigma Polishers are available in a variety of shapes and in three grit levels, giving technicians options for each step of porcelain finishing. Coarse polishers are used for contouring and shaping, medium polishers for blending and smoothing surfaces, and fine polishers for producing a natural high-gloss finish. The range of shapes allows technicians to work efficiently across different areas of a restoration, from broad surfaces to fine anatomical detail.

Additional Product Information

- Sold individually

- 104-HP shank size (2.35 mm)

- Manufactured in Germany

Resources

Technical Specifications

| Shape | Size | Optimal RPM | Maximum RPM |

|---|---|---|---|

| Knife-Edge | 26 mm x 2 mm | 6,000 rpm | 20,000 rpm |

| Wheel | 22 mm x 3.2 mm | 6,000 rpm | 20,000 rpm |

| Large Point | 5.5 mm x 18 mm | 6,000 rpm | 20,000 rpm |

| Small Point | 3.3 mm x 7.5 mm | 6,000 rpm | 20,000 rpm |

| Mounted Wheel | 11.5 mm x 2.4 mm | 6,000 rpm | 20,000 rpm |

| Disc | 19 mm x 0.5 mm | 6,000 rpm | 20,000 rpm |

Ordering Information

| Shape | Coarse (Blue) |

Medium (Red) |

Fine (Gray) |

|---|---|---|---|

| Knife-Edge | #51500 | #51530 | #51560 |

| Wheel | #51503 | #51533 | #51563 |

| Large Point | #51506 | #51536 | #51566 |

| Small Point | #51509 | #51539 | #51569 |

| Mounted Wheel | #51512 | #51542 | #51572 |

| Disc | #51515 | #51545 | #51575 |

Sigma Polishers FAQ

What materials can Sigma Polishers be used on?

Sigma Polishers are specifically designed for use on conventional feldspathic layering ceramics.

What speed should I use when operating Sigma Polishers?

The optimal speed for Sigma Polishers is 6,000 RPM, with a maximum speed of 20,000 RPM. For best results, refer to the product label or the chart on our website for specific speed recommendations based on the shape.

What kind of finish can Sigma Polishers achieve?

Sigma Polishers are designed to provide a smooth, high-gloss finish on conventional layering ceramics.

Can Sigma Polishers be used on zirconia or e.max?

Sigma Polishers are designed for conventional feldspathic ceramics, but some customers have successfully used them on other surfaces. Results may vary depending on the material and application.