What's the difference between all the Vacalon polishers?

08/20/2019

If you take a look at our rotary tools you might notice we've got a few different polishers in our lineup. So, what's the difference between all of them? What are they used for and why the different choices?

The answer is simple: The wide range of unique materials being used for restorations requires tools that are ideally suited to each material.

Here is a breakdown of each polisher and what materials they are used with.

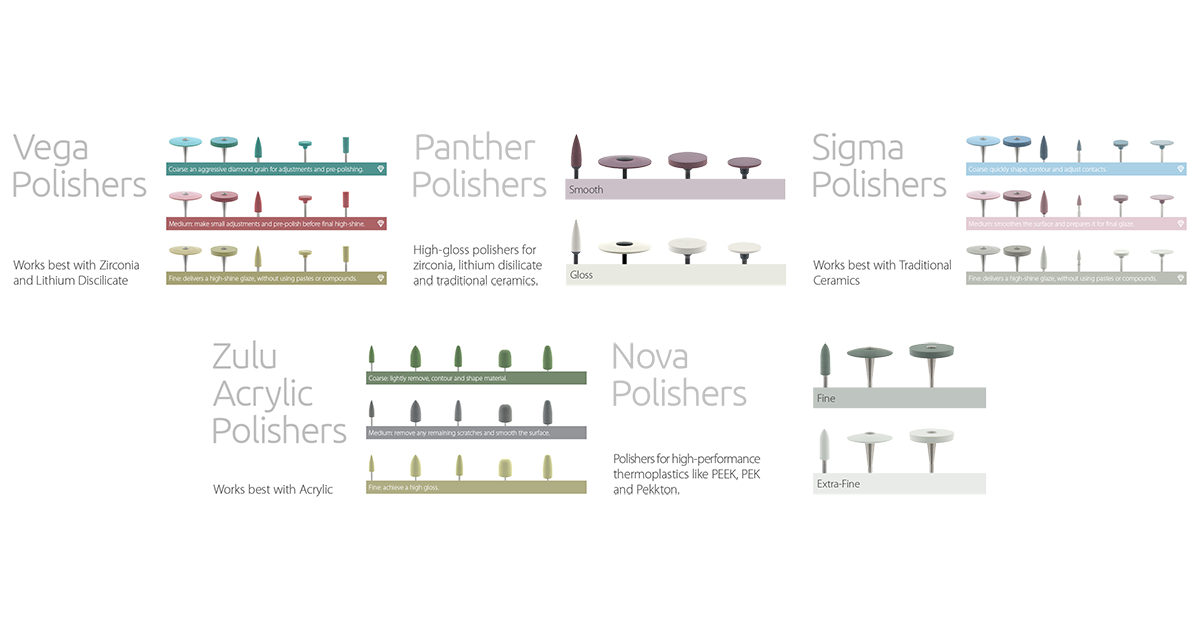

Vega Polishers

One of our most popular rotary tools, Vega Polishers are used with high-performance ceramics like Zirconia and Lithium Disilicate (e.max, LiSi, etc). They come in a coarse, medium or fine grit. Making them perfect for minor adjustments all the way to a high-glaze finish.

Panther Polishers

A newer polisher to our lineup, Panther Polishers were developed as a 2-step system that delivers a high-gloss finish on Zirconia and Lithium Disilicate. They are softer and more flexible, making them perfect for monolithic restorations.

Sigma Polishers

Designed to work with conventional feldspathic ceramics, Sigma Polishers can handle adjusting, smoothing and delivering a high-glaze finish without polishing compounds.

Zulu Polishers

These tools are designed for all types of acrylic - denture, orthodontic, milled PMMA, tray materials and more. Zulu Polishers have three grits that cover everything from adjustments to a high-shine.

Nova Polishers

The newest tool to our lineup, Nova Polishers were designed for high-performance themroplastics like PEEK, PEK and Pekkton. It's a 2-step system, covering smooth and adjusting, all the way to a high-gloss finish.